In the field of high-end material manufacturing, aluminum matrix composites are gradually becoming key and indispensable materials in industries such as aerospace, new energy vehicles, and precision electronics due to their lightweight, high strength, and wear resistance. However, due to the special material properties, it poses a great challenge to the mixing process.

A well-known aluminum matrix composite material manufacturer in Korea has approached us. They are currently confronted with industry pain points that traditional mixing equipment cannot overcome. Among the several materials involved in the mixing, such as aluminum powder and silicon carbide, there are significant differences in density and particle size. It is very difficult to meet the mixing process requirements with traditional mixers.

In the traditional mixing equipment, gravity convection diffusion causes the materials to freely fall and diffuse during the mixing process through the barrel rotation. However, the microscopic powders lack shear force, resulting in low mixing uniformity and even agglomeration.

The traditional forced shearing and stirring type has a large dead corner problem during the mixing process because the material barrel does not rotate, and its energy consumption is particularly high. These two types of equipment must not be used for materials with significant differences in density and particle size.

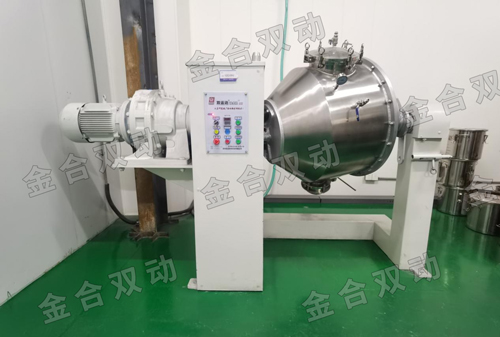

The customer is also well aware of the shortcomings of traditional mixers and has been constantly seeking new types of mixing equipment in the market. This time they found us and sent the materials over for the mixing experiment. The dual-motion mixer achieves the synchronous effect of macroscopic convection and microscopic shearing through the superposition of the dual movements of the rotation of the barrel and the stirring of the internal blades. It enables the mixed materials to achieve a uniform mixing degree in an extremely short time. The barrel rotates at a low and uniform speed to ensure the overall flow of materials. The blades shear at a medium speed to eliminate the agglomeration and stratification between microscopic particles. This design solves the pain points of traditional models, such as "low mixing efficiency" and "dead corners".